单螺口管箍

产品简介

详细信息

单螺口管箍

产品实物图:

|  |

| 锻制单螺口管箍 | 高压单螺口管箍 |

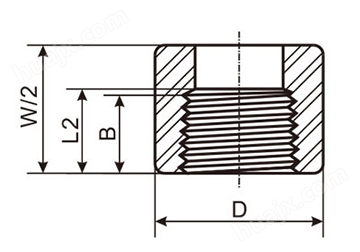

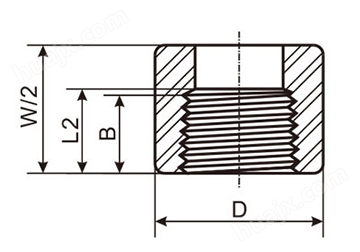

产品结构图:

|  |

锻制单螺口管箍 | 高压单螺口管箍 |

单螺口管箍产品参数表:

| 公称通径 Nominal Diameter | 长度 Center to End Coupling W | Center to End Cap P | 外径 Outside Diameter D | 壁厚 Minimum Wall Thickness G | 螺纹长度 Length Of Thread Min. | |||||

| B | L2 | |||||||||

| DN | NPS | 3000LB&6000LB | 3000LB Sch160 | 6000LB XXS | 3000LB Sch80 | 6000LB Sch160 | 3000LB XXS | 6000LB Sch80 | 3000LB Sch160 | 6000LB XXS |

| 6 | 1/8" | 32 | 19 | - | 16 | - | 4.8 | - | 6.4 | 6.7 |

| 8 | 1/4" | 35 | 25 | 27 | 19 | 25 | 4.8 | 6.4 | 8.1 | 10.2 |

| 10 | 3/8" | 38 | 25 | 27 | 22 | 32 | 4.8 | 6.4 | 9.1 | 10.4 |

| 15 | 1/2" | 48 | 32 | 33 | 28 | 38 | 6.4 | 7.9 | 10.9 | 13.6 |

| 20 | 3/4" | 51 | 37 | 38 | 35 | 44 | 6.4 | 7.9 | 12.7 | 13.9 |

| 25 | 1" | 60 | 41 | 43 | 44 | 57 | 9.7 | 11.2 | 14.7 | 17.3 |

| 32 | 1.1/4" | 67 | 44 | 46 | 57 | 64 | 9.7 | 11.2 | 17.0 | 18.0 |

| 40 | 1.1/2" | 79 | 44 | 48 | 64 | 76 | 11.2 | 12.7 | 17.8 | 18.4 |

| 50 | 2" | 86 | 48 | 51 | 76 | 92 | 12.7 | 15.7 | 19.0 | 19.2 |

| 65 | 2.1/2" | 92 | 60 | 64 | 92 | 108 | 15.7 | 19.0 | 23.6 | 28.9 |

| 80 | 3" | 108 | 65 | 68 | 108 | 127 | 19.0 | 22.4 | 25.9 | 30.5 |

| 100 | 4" | 121 | 68 | 78 | 140 | 159 | 22.4 | 28.4 | 27.7 | 33.0 |

| 备注: 1: 每种规格的上下值分别代表、最小尺寸。 2: 承插壁厚外围平均值不低于所列值,最小值于局部区域。 3: 上述单螺口管箍尺寸符合GB/T14383、GB/T14626、SH3410、HG/T21634、JIS B2316、ANSI B16.11、BS3799标准。 | ||||||||||

单螺口管箍生产工艺流程:

| 尺寸/Size | 1/8″~4″ (DN6~DN100) |

| 压力等级/Class | 2000 LBS, 3000 LBS, 6000 LBS |

| 连接形式/Type | Threads: American National Standard Taper Pipe Threads, NPT(ANSI/ASME B1.20.1-1983), Also available in other thread forms: Rc, Rp, BSP, BSPT,BSPP and in any combination. |

| 材质/Materal | 碳钢,不锈钢,合金钢,双相,镍合金,低温钢,铜镍 Stainless Steel, Alloy Steel, Duplex, Nickel Alloys, Low temperature Steel, Carbon Steel |

| 表面处理/Surface Treatment | 热浸镀锌、环氧树脂和FBE涂层、电抛光、喷砂、焊接 Hot Dipped Galvanizing, Epoxy & FBE Coating, Electro Polish, Sand Blasting, Soldering |

| 制造工艺/Manufacturing process | Cutting, Heat treatment, Forging, Machining 下料锯切、热处理、模锻、冲切边、喷砂、机械加工 |

| 制造标准/Manufacturing Standards | ANSI B16.11, GB/T4383-2018,BS-3799 |

单螺口管箍生产用材料等级:

| 碳钢/Carbon Steel | 20#, Q235B, ASTM/ ASME A 105, ASTM/ ASME A 350 LF 2 |

| 不锈钢/Stainless Steel | ASTM A182 F304, 304L, 316, 316L, 310S, 316Ti, 317L, 321 |

| 合金钢 /Alloy Steel | ASTM / ASME A 182, ASTM / ASME F5, F9, F11,F22, F 91 |

| 双相钢 /Duplex & Super Duplex Steel | ASTM A 182 – F51, F53, F55, S31803, S32205, S32550, S31254, SMO254, S32750, S32760, S32950. |

| 铜合金/Copper Alloy Steel | ASTM / ASME SB 111 UNS NO. C 10100 , C 10200 , C 10300 , C 10800 , C 12000, C 12200, C 70600 C 71500, ASTM / ASME SB 466 UNS NO. C 70600 ( CU -NI- 90/10) , C 71500 ( CU -NI- 70/30) |

| 镍合金 /Nickel Alloy | ASTM / ASME SB 336, ASTM / ASME SB 564 / 160 / 163 / 472, UNS 2200 (NICKEL 200) , UNS 2201 (NICKEL 201 ) , UNS 4400 (MONEL 400 ) , UNS 8020 ( ALLOY 20 / 20 CB 3 ) , UNS 8825 INCONEL (825) , UNS 6600 (INCONEL 600 ) , UNS 6601 (INCONEL 601) , UNS 6625 (INCONEL 625) , UNS 10276 (HASTELLOY C 276) |

单螺口管箍产品尺寸数据表:

| Socket Weld Pressure Class | Pipe Schedule | |||||||||

| Class 3000 | SHC80/XH | |||||||||

| Class 6000 | SHC160 | |||||||||

| Nominal Diameter | Center to End Coupling W | Center to End Cap P | Outside Diameter D | Minimum Wall Thickness G | Length Of Thread Min. | |||||

| B | L2 | |||||||||

| DN | NPS | 3000LB&6000LB | 3000LB Sch160 | 6000LB XXS | 3000LB Sch80 | 6000LB Sch160 | 3000LB XXS | 6000LB Sch80 | 3000LB Sch160 | 6000LB XXS |

| 6 | 1/8" | 32 | 19 | - | 16 | - | 4.8 | - | 6.4 | 6.7 |

| 8 | 1/4" | 35 | 25 | 27 | 19 | 25 | 4.8 | 6.4 | 8.1 | 10.2 |

| 10 | 3/8" | 38 | 25 | 27 | 22 | 32 | 4.8 | 6.4 | 9.1 | 10.4 |

| 15 | 1/2" | 48 | 32 | 33 | 28 | 38 | 6.4 | 7.9 | 10.9 | 13.6 |

| 20 | 3/4" | 51 | 37 | 38 | 35 | 44 | 6.4 | 7.9 | 12.7 | 13.9 |

| 25 | 1" | 60 | 41 | 43 | 44 | 57 | 9.7 | 11.2 | 14.7 | 17.3 |

| 32 | 1.1/4" | 67 | 44 | 46 | 57 | 64 | 9.7 | 11.2 | 17.0 | 18.0 |

| 40 | 1.1/2" | 79 | 44 | 48 | 64 | 76 | 11.2 | 12.7 | 17.8 | 18.4 |

| 50 | 2" | 86 | 48 | 51 | 76 | 92 | 12.7 | 15.7 | 19.0 | 19.2 |

| 65 | 2.1/2" | 92 | 60 | 64 | 92 | 108 | 15.7 | 19.0 | 23.6 | 28.9 |

| 80 | 3" | 108 | 65 | 68 | 108 | 127 | 19.0 | 22.4 | 25.9 | 30.5 |

| 100 | 4" | 121 | 68 | 78 | 140 | 159 | 22.4 | 28.4 | 27.7 | 33.0 |

1. Dimensions in Millimeters.

2. Dimensions refer to ANSI B16.11

3. Dimensions B is minimum length of perfect thread.

The length of useful thread(B plus threads with fully formed roots and flat crests) shall not be less than L2 (effective length of external thread) required by American National Standard for pipe threads(ANSI/ASME B1.20.1)

4. Dimensions of BSP and PTare available if required.

5. Dimensions may vary according to the customer's and manufacturer's requirement.