GHL系列高速混合制粒机

产品简介

详细信息

特 点Features

◎本机采用卧式圆简构造,结构合理。

◎充气密封驱动轴,清洗时可切换成水。

◎流态化造粒,成粒近似球形,流动性好。

◎较传统工艺减少25%粘合剂,干燥时间缩短。

◎每批次干混2分钟,造粒1-4分钟,工效比传统工艺提高4- -5倍。

◎在同一封闭容器内完成,干混湿混-制粒,工艺缩减,符合GMP规范。

◎This machine is of horizontal round and simple structure, with reasonable structure.

◎Inflatable sealing drive shaft can be switched to water during cleaning.

◎Fluidized granulation, the granulation is approximately spherical and has good fluidity.

◎Compared with the traditional process, the adhesive is reduced by 25%, and the drying time is shortened.

◎Each batch is dry mixed for 2 minutes and granulated for 1-4 minutes. The work efficiency is 4-5 times higher than that of the traditional process.

◎Completed in the same closed container, dry-mixed, wet-mixed, pelletized, with reduced process and conforming to GMP specifications.

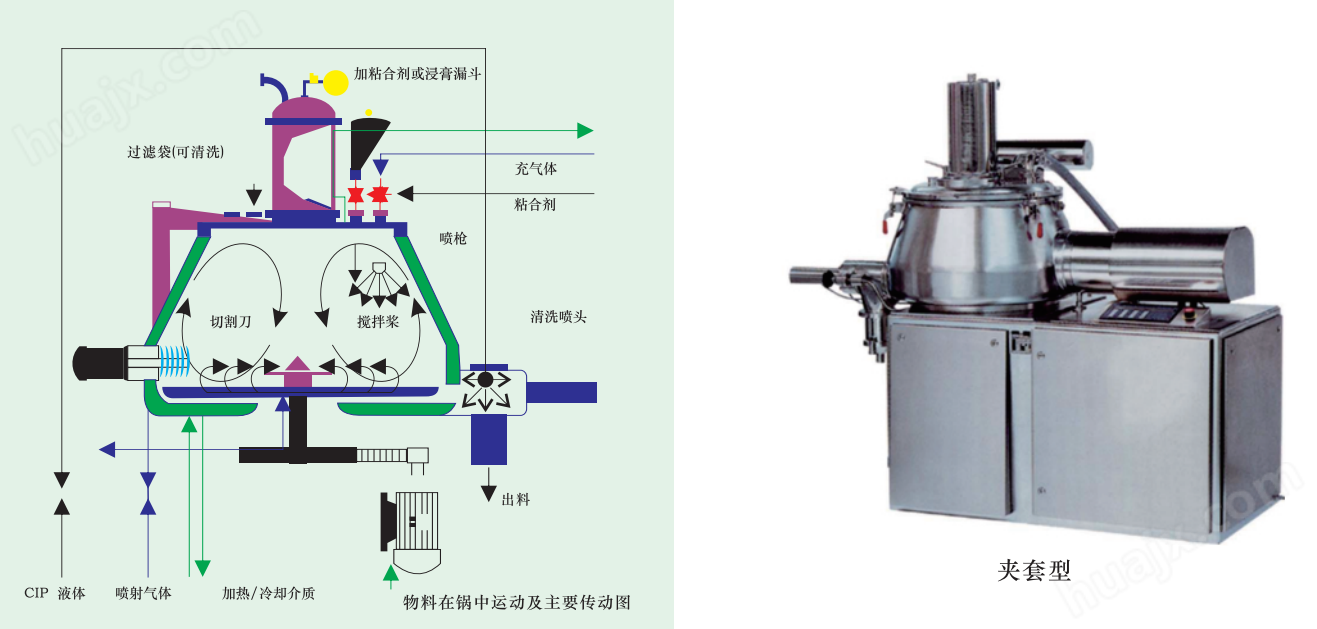

原理 Principles

粉体物料与粘合剂在圆简形容器中由底部混合桨充分混合成湿润软材,然后由侧置的高速粉碎桨切割成均匀的湿颗粒。

The powder material and the binder are fully mixed by the bottom mixing paddle into wet soft material in a round cylindrical container, and then are cut into uniform wet particles by the side high-speed crushing paddle.

夹套型工艺流程 Flow chart of jacket

技术参数 Technical parameters

| 名称 | 规格 | |||||||

| 10 | 50 | 150 | 200 | 250 | 300 | 400 | 600 | |

| 容积(L) | 10 | 50 | 150 | 200 | 250 | 300 | 400 | 600 |

| 产量(kg/batch) | 3 | 15 | 50 | 80 | 100 | 130 | 200 | 280 |

| 混合速度(r.p.m) | 300/600 | 200/400 | 180/270 | 180/270 | 180/270 | 140/220 | 106/155 | 80/120 |

| 混合功率(kw) | 1.5/2.2 | 4/5.5 | 6.5/8 | 9/11 | 9/11 | 13/16 | 18.5/22 | 22/30 |

| 切割速度(r.p.m) | 1500/3000 | 1500/3000 | 1500/3000 | 1500/3000 | 1500/3000 | 1500/3000 | 1500/3000 | 1500/3000 |

| 切割功率(kw) | 0.85/1.1 | 1.3/1.8 | 2.4/3 | 4.5/5.5 | 4.5/5.5 | 4.5/5.5 | 6.5/8 | 9/11 |

| 压缩空气耗量 (m3/min) | 0.6 | 0.6 | 0.9 | 0.9 | 0.9 | 1.1 | 1.5 | 1.8 |

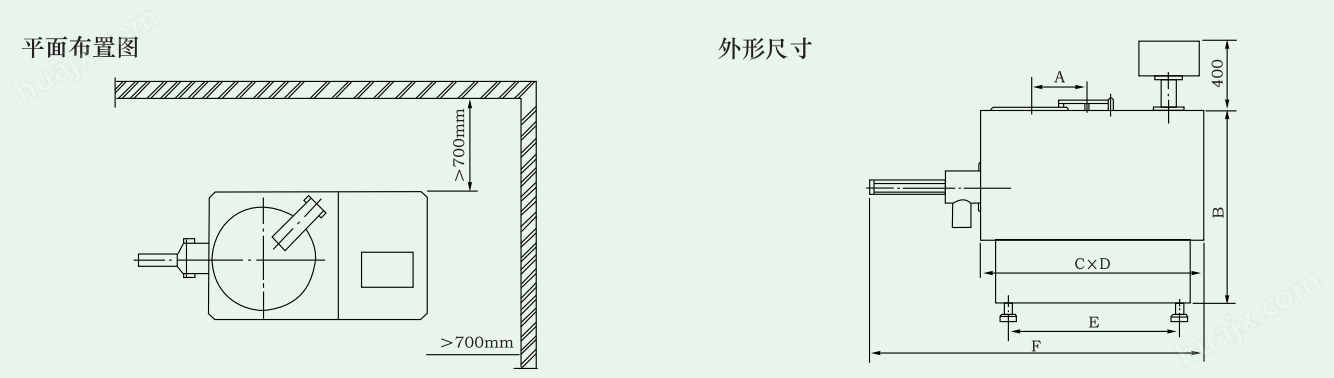

| 型号 | A | B | CXD | E | F |

| 10 | 270 | 750 | 1000x650 | 745 | 1350 |

| 50 | 320 | 950 | 1250x800 | 970 | 1650 |

| 150 | 420 | 1000 | 1350x800 | 1050 | 1750 |

| 200 | 500 | 1100 | 1650x940 | 1450 | 2050 |

| 250 | 500 | 1160 | 1650x940 | 1400 | 2260 |

| 300 | 550 | 1200 | 1700x1000 | 1400 | 2310 |

| 400 | 670 | 1300 | 1860x1100 | 1550 | 2410 |

| 600 | 750 | 1500 | 2000x1230 | 1750 | 2610 |