FSJG万通PP塑料斜流风机 耐酸碱防腐蚀实验室抽风加压用管道风机

产品简介

详细信息

-

FSJG型聚丙烯斜流风机

FSJG型聚丙烯斜流风机为鼓形结构,其进出口小的特点加快了气流速度、压力系数高。同一般轴流式风机同型号的情况下,其流量、压力均大于轴流式风机。该系列风机替代低压式风机,节能投资和占地、简化设计、安全安装。在轴流式风机压力满足不了的管道通风场合,使用斜流式管道风机是的选择。具有重量轻、耐腐性能良好、不易老化、噪音低等特点。广泛应用于工矿企业、宾馆、博物馆、体育馆、化工、实验室、环保配套设备等场所管道加夺压、抽排风使用。所输送气体不允许含有粘性物质、其所输送气体粉尘及硬质颗粒≤150mg/m2、气体温度≤60℃、相对湿度≤99%。 -

FSJG type polypropylene slanting fan

FSJG type glass fiber reinforced plastic/polypropylene slanting fan is a drum type structure. Its small import and export features speed up the speed of air flow and high pressure coefficient. With the same type of axial fan, the flow and pressure of the fan are greater than that of the axial flow fan. This series of fans replace the low pressure fan, energy saving investment and land occupation, simplified design, safe installation.In the pipe ventilation where the axial flow fan is unable to meet the pressure, the use of the inclined flow duct fan is the best choice. It has the characteristics of light weight, good corrosion resistance, not easy aging, low noise and so on. It is widely used in industrial and mining enterprises, hotels, museums, gymnasiums, chemical, laboratory and environmental protection facilities. The gas is not allowed to contain the viscous material, conveying gas dust and hard particles less than 150mg/m3, gas temperature are less than 60, the relative humidity is less than 99%.

| 机 号 Model(No) | ||||

|---|---|---|---|---|

| 功 率 Power(Kw) | 转 速 Speed(r/min) | 流 量 Volume(M3/h) | 全 压 Pressure(Pa) | |

| 2.5F | 0.12 | 1450 | 360-1500 | 50-170 |

| 3.0F | 0.18 | 1450 | 600-2520 | 80-250 |

| 3.5S | 0.18 | 960 | 600-2600 | 50-150 |

| 3.5F | 0.37 | 1450 | 1020-4020 | 100-340 |

| 4.0S | 0.25 | 960 | 900-4020 | 60-200 |

| 4.0F | 0.75 | 1450 | 1500-5160 | 200-400 |

| 4.5S | 0.37 | 960 | 1260-4980 | 100-250 |

| 4.5F | 1.1 | 1450 | 1980-8000 | 200-560 |

| 5.0S | 0.75 | 960 | 2300-7200 | 100-300 |

| 5.0F | 2.2 | 1450 | 3420-9540 | 300-700 |

| 6.0S | 1.5 | 960 | 2520-10200 | 200-500 |

| 6.0F | 5.5 | 1450 | 7020-11580 | 300-900 |

| 7.0S | 3 | 960 | 4020-11400 | 300-600 |

| 8.0S | 7.5 | 960 | 7846-16580 | 320-700 |

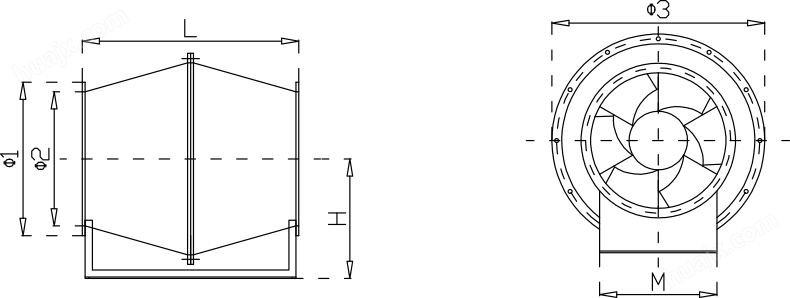

外形及安装尺寸示意图 Lnstallation size diagram

产品为人工实物测量会有一定误差,相关数据仅作参考,以收到的实物为准。 单位Unit: mm(毫米)

| 机 号 | ||||||

|---|---|---|---|---|---|---|

| 外形尺寸Shape size | ||||||

| No | L | H | Φ1 | Φ2 | Φ3 | M |

| 2.5F | 387 | 256 | 342 | 252 | 404 | 342 |

| 3.0F | 443 | 283 | 405 | 305 | 489 | 410 |

| 3.5S | 500 | 290 | 410 | 380 | 560 | 440 |

| 3.5F | 500 | 290 | 410 | 380 | 560 | 440 |

| 4.0S | 520 | 320 | 480 | 400 | 630 | 510 |

| 4.0F | 520 | 320 | 480 | 400 | 630 | 510 |

| 4.5S | 560 | 370 | 530 | 450 | 670 | 560 |

| 4.5F | 560 | 370 | 530 | 450 | 670 | 560 |

| 5.0S | 650 | 410 | 580 | 500 | 770 | 610 |

| 5.0F | 650 | 410 | 580 | 500 | 770 | 610 |

| 6.0S | 800 | 490 | 680 | 600 | 910 | 710 |

| 6.0F | 800 | 490 | 680 | 600 | 910 | 710 |

| 7.0S | 840 | 530 | 780 | 700 | 1000 | 810 |

| 8.0S | 1000 | 640 | 880 | 800 | 1145 | 910 |