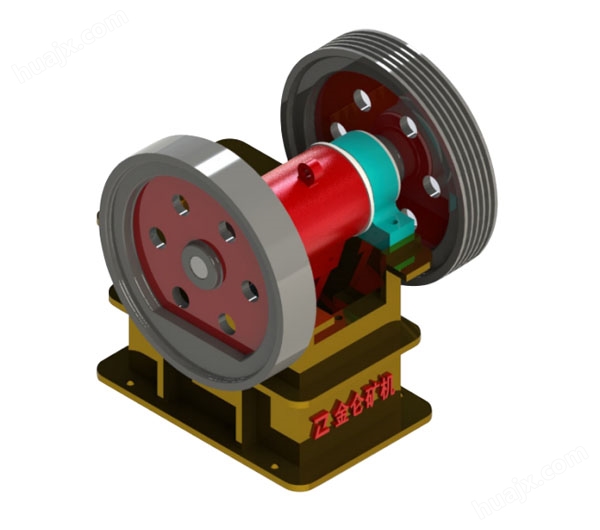

鄂式破碎机-JL系列颚式破碎机

产品简介

详细信息

鄂式破碎机主要用于对各种矿石或大块物料进行中等粒度的破碎。按照进料口宽度大小来分为大、中、小型三种,进料口宽度大于600mm的为大型机,进料口宽度在300-600mm的为中型机,进料口宽度小于300mm的为小型机。颚式破碎机(简称:鄂破)广泛应用于矿山、冶炼、建材、公路、铁路、水利和化工等行业。被破碎物料的******抗压强度为320Mpa。

Jaw Crusher is mainly used to crush various medium particle size of ores or large materials. According to the feed inlet width, it can be divided into three types: large, medium and small. Large machines are those with a feeding width over 600mm; medium machines are those with a feeding width of 300-600mm; small machines are those with a feeding width smaller than 300mm. Jaw Crusher (abbreviated as J Crusher) is widely used in mine, metallurgy, building, material, highway, rail way, hydraulic engineering and chemical industry, etc. The maximum compressive resistance of the crushed materials is 320Mpa.

技术优势和特点/ TECHNICAL ADVANTAGES AND CHARACTERISTICS

●其破碎比大,产品粒度均匀;破碎腔深而且无死区,提高了进料能力与产量;

The crushing ratio is big with a uniform product granularity; the crushing cavity is deep with no dead zone, thus improving the feeding capacity and output;

●垫片式排料口调整装置,可靠方便,调节范围大,增加了设备的灵活性;

The adjusting device of gasket-type outlet orifice is reliable and convenient, with a large adjusting range, which increases the flexibility of the machine;

●排料口调整范围大,可满足不同用户的要要求;设备节能:单机节能15%~30%,系统节能一倍以上;噪音低,粉尘少;

The adjustment range of outlet orifice is large, which can meet the requirements of different users; energy-saving equipment: The energy saving of a single machine is 15%-30%, and the system's energy saving is more than double of that; low noise and little dust.

●润滑系统安全可靠,部件更换方便,保养工作量小;结构简单,工作可靠,运营费用低。

The lubrication system is safe and reliable, with convenient part replacement and little maintenance work; the structure is simple with a reliable performance low operating cost.

工作原理/ OPERATING PRINCIPLE

鄂式破碎机的工作部分由两块鄂板构成,固定鄂板(定鄂),垂直(或上端略外倾)固定在机体前壁上,另一个是活动鄂板(动鄂),位置倾斜,与固定鄂板形成上大下小的破碎腔(工作腔)。活动鄂板对着固定鄂板做周期性的往复运动,时而分开,时而靠近。分开时,物料进入破碎腔,成品从下部卸出;靠近时,使装在两块鄂板之间的物料受到挤压、弯折和劈裂作用而破碎。

The working parts of the Jaw Crusher consist of two jaw plates. The fixed jaw plate (fixed jaw) is fixed on the front wall of the machine body vertically (or the top tip slightly outward). The other is rotating jaw plate (rotating jaw), which is inclined in its position. And the two jaw plates form a crushing cavity (working cavity) with large top and small bottom. The rotating jaw plate is reciprocating periodically against the fixed jaw plate, sometimes separately and sometimes closely. When they are separated, the materials enter the crushing cavity, and the finished products are unloaded from the lower part; when they are approaching, the material loaded between the two jaw plates is crushed by the effects of extrusion, bending and splitting.