品牌

生产厂家厂商性质

东莞市所在地

DDS大型除湿干燥机系统应用於塑胶使用大且露点要求低的场合。本公司制造的大型除湿干燥系统用於处理PET原料时zui高可达800kg/h。该系统主要包含每小时干燥风量zui高4.000m3的蜂巢转轮式除湿机及容料量高达8.000L(於装载PET时的有效重量为6.400kg)的保温式干燥料桶,经由转轮除湿机处理过后的干燥原料zui终含水率zui高可以达到0.004%以下。

Large dehumidifying drying system

When you need to use large quantity of plastic and lower dew-point, you should choose DDS series large dehumidifying drying systems.

DDS series' capacity can reach 8000kg/h. This system includes honeycomb rotor dehumidier(8000m3/h) and insulation hopper

(10000L or 8000kg PET). After treatment, the highest rate of dry raw material can reach the nal moisture content below 0.004%.

本机特点:

1. 定速搅拌设计使未结晶之塑料在晶相化的制程温度中不沾结成块;

2. 结晶效率高且均匀;

3. 可以简化并提高原料干燥时的效率;

4. 原料干燥可以在高温下进行 , 并且干燥过程可以直接使用现有的标准干燥料桶;

5. 制程温度可透过温控器进行准确控制;

6. 增加回收料在 PET 新料中的使用比例;

7. 可搭配除湿机 , 直接执行除湿作业;

8. 可选配螺旋送料装置定量输出已结晶原料。

Proudcts Features

1. Constant speed stirring uncrystallized designed so that the plastic does not stick

in the temperature of the crystalline phase of the process to form blocks;

2. Crystallization eciency is high and uniform;

3. It can simplify and improve the eciency of the raw material drying process;

4. Drying of the raw material can be performed at high temperature, and the drying

process can be used directly to the existing standard drying drum;

5. Process temperature can be accuray controlled by thermostat;

6. Increase the proportion of recycled material in the use of new PET material;

7. it is optional of the dehumidier that can directly perform the dehumidication work.;

8. Optional screw feeding device output the crystallized material quantitatively.

规格表 Specifications

产品规格若有变更,恕不另行通知

The specification is subject to change without prior notice.

机型(KG) Model | NCR-160L | NCR-450L | NCR-900L | NCR-1600L | NCR-2500L |

装料量(Kg) | 100 | 300 | 600 | 1000 | 1500 |

搅拌电机功率(KW) | 0.25 | 1.1 | 1.5 | 1.5 | 2.2 |

风机功率(Kw) | 0.55 | 2.2 | 3 | 11 | 15 |

电热功率(Kw) | 12 | 24 | 48 | 86 | 134 |

zui大处理量(kg/hr) | 55 | 150 | 300 | 500 | 750 |

☆机器电压规格为 :3¢,400V,50Hz.

The specification is subject to change without prior notice.

干燥能力参照表 Specifications for Drying Capacity

| 原料 | 干燥 温度 | 干燥 时间 | 比热 | 原料 比重 | 除湿 前含 水率 | 除湿 后含 水率 | 干燥能力 | ||||||||||||||

| ND-30 | 50 | 80 | 120 | 150 | 200 | 300 | 400 | 500 | 700 | 1000 | 1500 | 2000 | 3000 | 4000 | |||||||

| ABS | 80 | 2-3 | 0.34 | 0.6 | 0.3 | 0.02 | 11 | 18 | 27 | 35 | 71 | 200 | 180 | 210 | 285 | 355 | 425 | 710 | 1065 | 1500 | 1600 |

| CA | 75 | 2-3 | 0.5 | 0.5 | 1 | 0.02 | 9 | 15 | 22 | 30 | 60 | 105 | 150 | 180 | 235 | 295 | 355 | 590 | 885 | 1200 | 1330 |

| CAB | 75 | 2-3 | 0.5 | 0.5 | 0.8 | 0.02 | 9 | 15 | 22 | 30 | 60 | 90 | 150 | 180 | 235 | 295 | 355 | 590 | 885 | 1200 | 1330 |

| CP | 75 | 2-3 | 0.6 | 0.6 | 1 | 0.02 | 11 | 18 | 27 | 35 | 71 | 90 | 180 | 210 | 235 | 355 | 425 | 710 | 1060 | 1500 | 1600 |

| LCP | 150 | 4 | 0.6 | 0.6 | 0.04 | 0.02 | 8 | 13 | 20 | 27 | 55 | 106 | 135 | 160 | 210 | 265 | 320 | 530 | 800 | 1150 | 1200 |

| POM | 100 | 2 | 0.35 | 0.6 | 0.2 | 0.02 | 16 | 27 | 40 | 53 | 105 | 80 | 265 | 320 | 425 | 530 | 640 | 1060 | 1600 | 1800 | 2400 |

| IONOMER | 90 | 3-4 | 0.55 | 0.5 | 0.1 | 0.04 | 7 | 11 | 17 | 22 | 44 | 160 | 111 | 133 | 177 | 220 | 265 | 442 | 663 | 750 | 1000 |

| PA6/6.6/6.10 | 75 | 4-6 | 0.4 | 0.65 | 1 | 0.05 | 6 | 10 | 14 | 19 | 38 | 66 | 96 | 115 | 153 | 192 | 230 | 383 | 575 | 960 | 1040 |

| PA11 | 75 | 4-5 | 0.58 | 0.65 | 1 | 0.05 | 7 | 12 | 17 | 23 | 46 | 58 | 115 | 138 | 184 | 230 | 275 | 460 | 690 | 780 | 1150 |

| PA12 | 75 | 4-5 | 0.28 | 0.65 | 1 | 0.05 | 7 | 12 | 17 | 23 | 46 | 69 | 115 | 138 | 184 | 230 | 275 | 460 | 690 | 780 | 1150 |

| PC | 120 | 2-3 | 0.28 | 0.7 | 0.3 | 0.01 | 13 | 21 | 31 | 41 | 83 | 69 | 206 | 250 | 330 | 413 | 495 | 826 | 1238 | 1400 | 1860 |

| PU | 90 | 2-3 | 0.45 | 0.65 | 0.3 | 0.02 | 11 | 19 | 29 | 38 | 77 | 124 | 190 | 230 | 307 | 383 | 460 | 767 | 1150 | 1530 | 2080 |

| PBT | 130 | 3-4 | 0.3-0.5 | 0.7 | 0.2 | 0.02 | 9 | 15 | 23 | 31 | 62 | 115 | 155 | 186 | 248 | 310 | 372 | 620 | 930 | 1100 | 1600 |

| PE | 90 | 1 | 0.55 | 0.6 | 0.01 | <0.01 | 32 | 53 | 80 | 106 | 212 | 93 | 531 | 637 | 850 | 1065 | 1275 | 2125 | 3185 | 3600 | 4800 |

| PEI | 150 | 3-4 | 0.6 | 0.6 | 0.25 | 0.02 | 8 | 13 | 20 | 27 | 53 | 318 | 133 | 160 | 212 | 265 | 320 | 530 | 800 | 1030 | 1370 |

| PET | 160 | 4-6 | 0.3-0.5 | 0.85 | 0.2 | 0.05 | 8 | 13 | 19 | 25 | 50 | 80 | 125 | 150 | 200 | 250 | 300 | 500 | 750 | 1150 | 1360 |

| PETG | 70 | 3-4 | 0.6 | 0.6 | 0.5 | 0.02 | 8 | 13 | 20 | 27 | 53 | 75 | 133 | 160 | 212 | 265 | 320 | 530 | 800 | 1030 | 1370 |

| PEN | 170 | 5 | 0.85 | 0.85 | 0.1 | 0.05 | 9 | 15 | 23 | 30 | 60 | 90 | 150 | 180 | 240 | 300 | 360 | 600 | 900 | 1150 | 1360 |

| PES | 150 | 4 | 0.7 | 0.7 | 0.8 | 0.02 | 9 | 15 | 23 | 30 | 60 | 90 | 150 | 180 | 240 | 630 | 360 | 600 | 900 | 1050 | 1400 |

| PMMA | 80 | 3 | 0.65 | 0.65 | 0.5 | 0.02 | 11 | 19 | 29 | 38 | 77 | 115 | 190 | 230 | 310 | 385 | 460 | 765 | 1150 | 1530 | 1730 |

| PPO | 110 | 1-2 | 0.4 | 0.5 | 0.1 | 0.04 | 13 | 22 | 33 | 44 | 88 | 133 | 220 | 265 | 355 | 440 | 530 | 885 | 1330 | 1730 | 2660 |

| PPS | 150 | 3-4 | 0.6 | 0.6 | 0.1 | 0.02 | 8 | 13 | 20 | 27 | 53 | 80 | 133 | 160 | 212 | 265 | 320 | 530 | 800 | 1030 | 1370 |

| PU | 120 | 2 | 0.27 | 0.6 | 0.4 | 0.02 | 16 | 27 | 40 | 53 | 105 | 160 | 265 | 320 | 425 | 530 | 640 | 1060 | 1600 | 1800 | 2400 |

| PP | 90 | 1 | 0.46 | 0.5 | 0.1 | 0.02 | 26 | 44 | 66 | 88 | 180 | 265 | 442 | 530 | 710 | 885 | 1060 | 1770 | 2655 | 3500 | 4000 |

| GP(GP) | 80 | 1 | 0.28 | 0.5 | 0.1 | 0.02 | 26 | 44 | 66 | 88 | 180 | 265 | 442 | 531 | 708 | 885 | 1062 | 1770 | 2655 | 3500 | 4000 |

| PSU | 120 | 3-4 | 0.31 | 0.65 | 0.3 | 0.02 | 8 | 14 | 22 | 29 | 60 | 85 | 145 | 173 | 230 | 290 | 345 | 575 | 865 | 1300 | 1485 |

| PVC | 70 | 1-2 | 0.2 | 0.5 | 0.1 | 0.02 | 13 | 22 | 33 | 44 | 90 | 135 | 220 | 265 | 355 | 442 | 530 | 885 | 1330 | 1730 | 2660 |

| PAN(AS) | 80 | 14-2 | 0.32 | 0.5 | 0.1 | 0.05 | 13 | 22 | 33 | 44 | 90 | 135 | 220 | 265 | 355 | 442 | 530 | 885 | 1330 | 1730 | 2660 |

| TPE | 110 | 3 | 0.7 | 0.7 | 0.1 | 0.02 | 13 | 20 | 30 | 40 | 85 | 125 | 205 | 250 | 330 | 413 | 495 | 826 | 1238 | 1650 | 1860 |

☆如何选择所需之除湿机的机型:为达到*效率,

请取干燥能力表的 80%,

对照所需的原料及干燥能力,即可寻得正确的机型

例如:欲干燥 80kg/hr 的 PET,则 ND-300 即为适当的选择

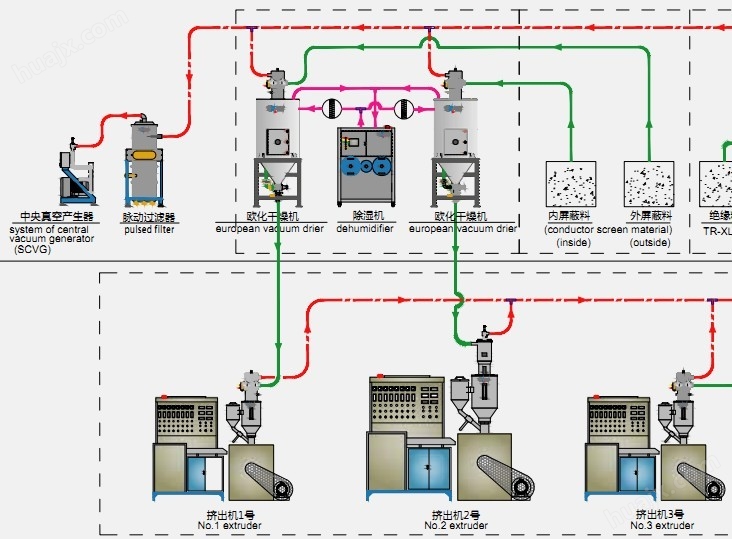

东莞市尼嘉斯塑胶机械有限公司:尼嘉斯--节能管控,改观现状,异军突起的思维累积专业制造经验--25年塑厂流程设备;整体规划*实力--南亚、台塑、中华各大塑业集园(23年佳绩);行遍东南亚各国大厂--现场施作10T--2000T储槽;塑料专业流程经历--与日本,德国,美国挤出成型设计配套!

东莞市尼嘉斯塑胶机械有限公司:尼嘉斯--节能管控,改观现状,异军突起的思维累积专业制造经验--25年塑厂流程设备;整体规划*实力--南亚、台塑、中华各大塑业集园(23年佳绩);行遍东南亚各国大厂--现场施作10T--2000T储槽;塑料专业流程经历--与日本,德国,美国挤出成型设计配套!

东莞市尼嘉斯塑胶机械有限公司 地 址:广东省东莞市常平镇漱旧工业区工业二路1号电 话: 手 机:联 系 人:梁传 真:86-769-81012877邮 箱:niasi@niasi.cn公司:www.niasi.cn